Biomimetic Factories: Nature-Inspired Designs Revolutionizing Industrial Processes

Imagine a factory that operates with the efficiency of a beehive, adapts like a chameleon, and self-heals like human skin. This isn't science fiction—it's the cutting-edge realm of biomimetic factories. By mimicking nature's time-tested strategies, industries are reimagining production processes, waste management, and energy utilization, paving the way for a new era of sustainable and highly efficient manufacturing.

The Genesis of Biomimetic Factories

The concept of biomimetic factories isn’t entirely new, but its application on an industrial scale is a recent development. Historically, engineers and designers have long looked to nature for inspiration. Leonardo da Vinci’s flying machines were inspired by birds, and the Wright brothers studied pigeons to crack the code of flight. However, it wasn’t until the late 20th century that biomimicry emerged as a formal discipline, thanks to pioneers like Janine Benyus, who coined the term in her 1997 book “Biomimicry: Innovation Inspired by Nature.”

In the industrial context, the shift towards biomimetic design began as manufacturers sought ways to improve efficiency and sustainability. Traditional factories, with their rigid structures and linear processes, were increasingly seen as outdated in a world demanding flexibility and environmental responsibility. The biomimetic approach offered a solution: by emulating nature’s circular systems and adaptive strategies, factories could become more resilient, efficient, and environmentally friendly.

Core Principles of Biomimetic Factory Design

Biomimetic factories operate on several key principles derived from natural systems:

-

Circular Resource Use: Just as in nature, where waste from one process becomes food for another, biomimetic factories aim for zero waste by designing closed-loop systems.

-

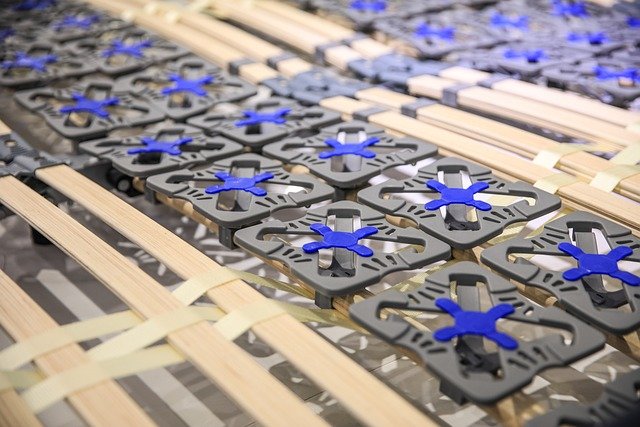

Adaptive Flexibility: Like organisms that adapt to changing environments, these factories are designed to quickly reconfigure processes in response to market demands or resource availability.

-

Energy Efficiency: Inspired by how plants capture and use solar energy, biomimetic factories incorporate innovative energy harvesting and conservation techniques.

-

Self-Healing and Maintenance: Drawing from biological self-repair mechanisms, these facilities incorporate materials and systems that can detect and fix minor damages autonomously.

-

Symbiotic Relationships: Mirroring ecosystems where different species benefit from each other, biomimetic factories often form industrial symbioses with neighboring facilities to share resources and byproducts.

Innovative Applications in Current Industries

Several industries are at the forefront of implementing biomimetic principles in their manufacturing processes:

-

Automotive Manufacturing: Some car manufacturers are redesigning their paint shops to mimic the water-preserving techniques of desert beetles, significantly reducing water usage and chemical waste.

-

Textile Production: Inspired by spider silk, companies are developing ultra-strong, biodegradable fibers that require less energy to produce and are fully recyclable.

-

Building Materials: Cement factories are adopting coral-inspired carbon capture techniques, turning CO2 emissions into usable construction materials.

-

Food Processing: Biomimetic filtration systems based on the structure of animal kidneys are revolutionizing liquid purification in beverage production, reducing energy consumption and improving product quality.

Challenges and Future Prospects

While the potential of biomimetic factories is immense, challenges remain. The complexity of natural systems can make them difficult to replicate in industrial settings. Moreover, the initial investment required for overhauling existing facilities can be substantial. However, as technology advances and more success stories emerge, the adoption of biomimetic principles is likely to accelerate.

Looking ahead, the future of biomimetic factories is incredibly promising. Advancements in materials science, particularly in the field of smart materials that can change properties in response to stimuli, are opening new possibilities for adaptive manufacturing systems. Additionally, the integration of artificial intelligence and machine learning is enabling factories to mimic nature’s problem-solving abilities more closely, leading to unprecedented levels of efficiency and innovation.

Key Insights for Industry Leaders

• Conduct a biomimicry audit of your current processes to identify areas where nature-inspired solutions could improve efficiency.

• Invest in research partnerships with biomimicry experts and institutions to stay at the forefront of this emerging field.

• Consider the long-term benefits of biomimetic systems, which often show improved resilience and sustainability over traditional methods.

• Implement pilot projects to test biomimetic solutions in specific areas of your operations before full-scale adoption.

• Educate your workforce on biomimicry principles to foster a culture of nature-inspired innovation throughout your organization.

As we stand on the brink of a new industrial era, biomimetic factories offer a compelling vision of the future—one where industry and nature work in harmony rather than opposition. By learning from and emulating the genius of natural systems, we can create manufacturing processes that are not only more efficient and profitable but also regenerative and sustainable. The biomimetic revolution in industry is more than just a trend; it’s a fundamental shift in how we approach design, production, and resource management, promising to reshape the industrial landscape for generations to come.